Paving Stone and Briquette Machine Pallets

Concrete paving stone machine pallets which must have the characteristics: conditions unpretentious, durable and cheap. The material in which it is made must transmit vibration, keep it in shape and must be resistant to moisture.

Is there an ir ideal den structure and what should be expected from the actual manufacturing pallets?

In our company, production pallets made of wood material for the concrete paving stone machine and briquette machine can be purchased.

FEATURE OF HER RAW 6:

Technological polymer pallets are resistant to moisture, can also be used for curing rooms

Can be used in wood with a moisture content of less than 60% (standard humidity in summer is 80%)

The polymer product evenly transmits the mechanical vibrations of the concrete paving stone machine during its lifetime

The wooden structure retains the incoming vibration transmission and must be renewed in two years due to its strength reduction.

Polymer retains its shape and integrity during the use of the pallet

Wood cracks and becomes dry due to temperature / humidity

Resistant to polymer vapor, this concrete paving machine can also be used for bu curing ines manufacturing pallets

Steam causes timber to wear out quickly

The lifetime of the polymer pallet is 2880 cycles (pressing)

The usage time of the wooden pallet is 720 cycles (pressing)

Polymer conditions are unpretentious, no special treatment required

Wood preservative impregnation and special storage conditions

OTHER SERVICES

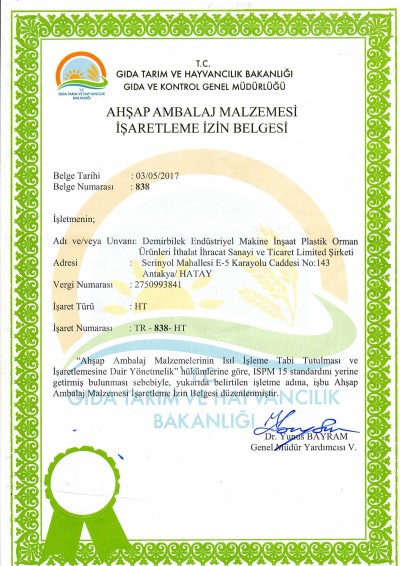

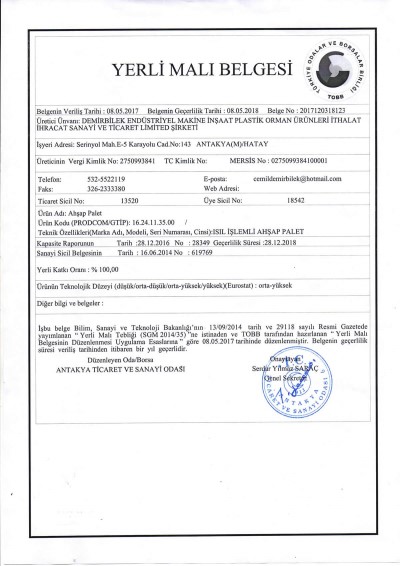

Heat Treated PalletŞub 2, 2019

In wooden packaging materials, the temperature is gradually increased to 56 ° C and then it is waited for ...

More

Special Production PalletsOca 26, 2019

It is the type of pallet made in special sizes upon the requests of the companies. Measurements can be made as desired.

More

Heavy Industry and Container PaletteOca 19, 2019

The container pallets used in heavy industry are produced by our company carefully.

More

Desired Sizes of Lumber ProductionOca 5, 2019

It is called mamüle timber, which is obtained by mowing and sawing logs in certain standards and sizes.

More

Euro Shipping PalletsAra 29, 2018

Pallets are standardized to measure, quality, material type, ratio and used nails in accordance with European Standards.

More